The conversation around bringing fashion and apparel manufacturing back to the United States has grown louder in recent months as tariff news continues to hit the stands—especially as 97% of goods in the industry are imported. For many, the idea seems aspirational; limited by high labor costs, outdated infrastructure and a lack of technical workforce, the barriers appear to be high. But we’re at a critical inflection point. Automation and artificial intelligence (AI) have matured to the point where reshoring is not only possible—it is practical given the right circumstances.

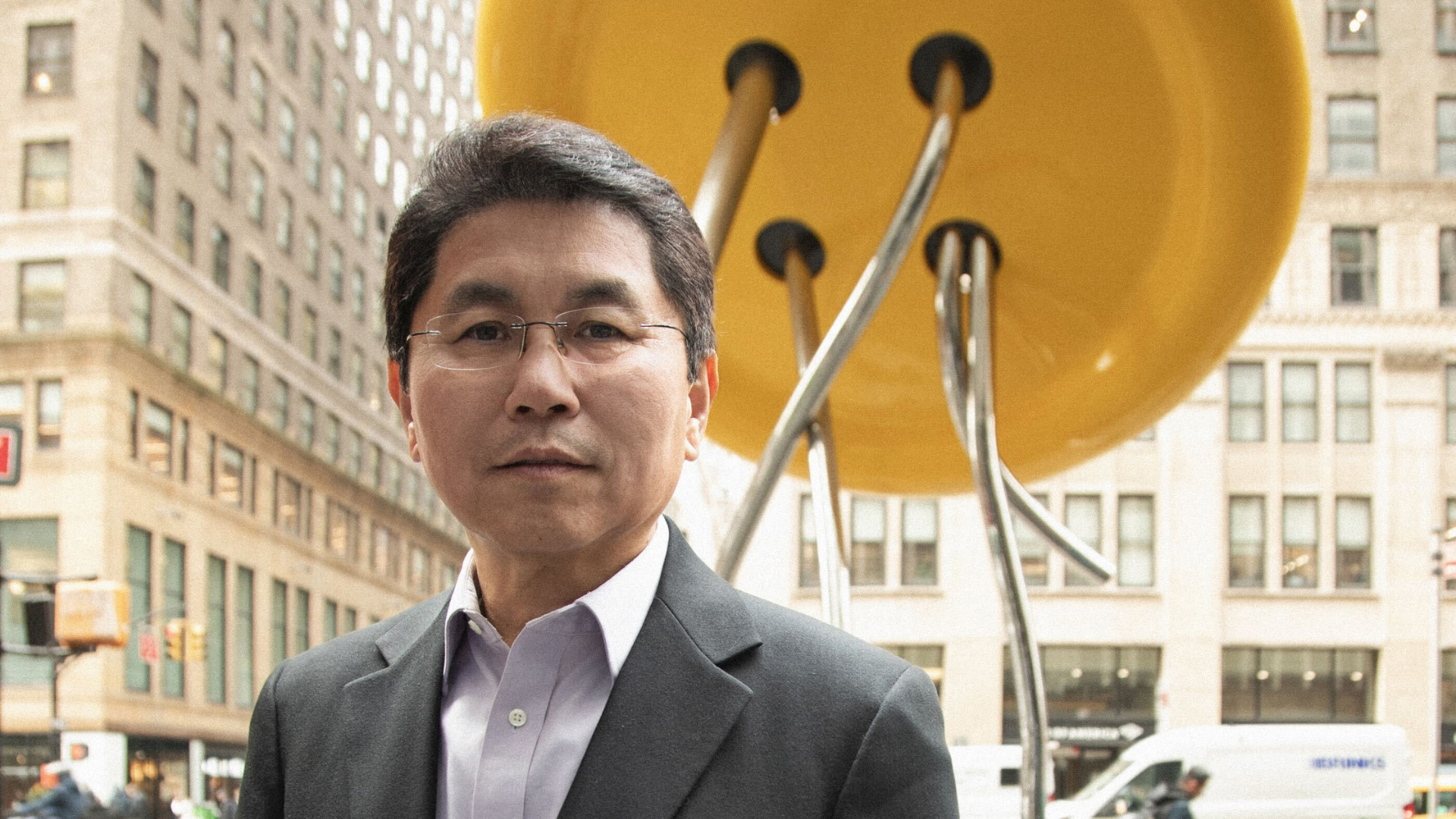

Our CEO, Max Ma, shared his opinion on reshoring for fashion and apparel with Sourcing Journal: https://sourcingjournal.com/topics/technology/reshoring-immigration-technology-manufacturing-trump-made-in-america-1234749503/

There was a time when regions across the country were thriving apparel production hubs. Factories operated efficiently, often powered by skilled immigrant labor and close ties to local retailers. That ecosystem didn’t vanish because it was inherently flawed, it shifted overseas due to cost advantages. Today, however, the dynamics have changed. Labor costs in countries like China have risen significantly, while regulatory burdens and global instability have introduced new risks into extended supply chains.

Meanwhile, pockets of domestic production still exist. Lower-cost regions such as South Carolina maintain infrastructure and history in apparel manufacturing, and niche factories continue to operate in urban centers like Brooklyn, New York. The conditions for regrowth are in place. What is needed is an alignment in policy, technology and the industry’s commitment.

The Role of AI in a Reshoring Revolution

Automation and AI are the great equalizers in the reshoring conversation. Dark factories have been seen in other industries—so it’s not unfounded that they could be possible for fashion as well but it’s unlikely apparel manufacturing will be entirely human-free; significant portions of the production process from fabric cutting, dyeing, material transport and even quality control, can be automated today. These advancements dramatically reduce dependency on manual labor while increasing output consistency.

Beyond the factory floor, AI-driven platforms like 7thonline are already transforming how retailers plan and manage inventory. By automatically generating merchandise plans based on historical data and predictive analytics, retailers can reduce overproduction, avoid lost sales and respond more quickly to changing demand. These benefits are particularly compelling when paired with shorter, domestic supply chains.

When production happens thousands of miles away, a single purchase decision can take months to reach the sales floor. The risk of misalignment is high. Reshoring, supported by intelligent planning systems, drastically reduces that lag and associated costs.

Policy Must Match Industry Momentum

For this reshoring vision to become a reality at scale, government support is essential. Other countries that have successfully built automated manufacturing sectors, such as Japan, South Korea and China, have done so with significant public investment. These governments have subsidized robotics, funded workforce training and created tax incentives to attract industrial development.

The United States should review success stories and take inspiration while following suit. Subsidies for automation equipment, tax incentives for reshoring investments and grants for workforce development would create a more level playing field. These policies should be considered industrial aid because they are strategic investments that can lead to job creation, higher tax revenue and greater national resilience.

Looking Ahead: A Smarter Supply Chain

The time to act is sooner rather than later. The fashion and retail industries are under immense pressure to improve speed to market, reduce waste and operate more sustainably. Especially as tariff uncertainty continues to hit the newsstands. A smarter, more localized supply chain that’s enabled by automation and powered by AI is the solution.

As we look to the future, the question is no longer whether reshoring is possible. The question is: are we ready to do the work collectively, across sectors and with government support to make it happen? With the right combination of policy, technology and willpower, we can build a new era of American manufacturing. One that is more intelligent, responsive and resilient than ever before.

7thonline is a global leader in AI-native demand planning and inventory management solutions, offering retailers and wholesalers innovative functionality that optimizes their supply chains and drives profitability across all key channels. To learn more about our merchandise software solution, contact the team at info@7thonline.com or book a demo.